You have found www.hamrx8.com

Copyright.... Website created & maintained by GHQP

Page Updated

June 11th 2015

June 11th 2015

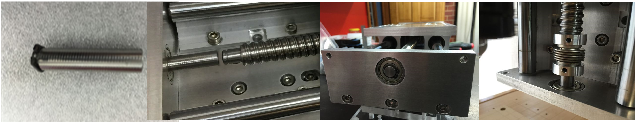

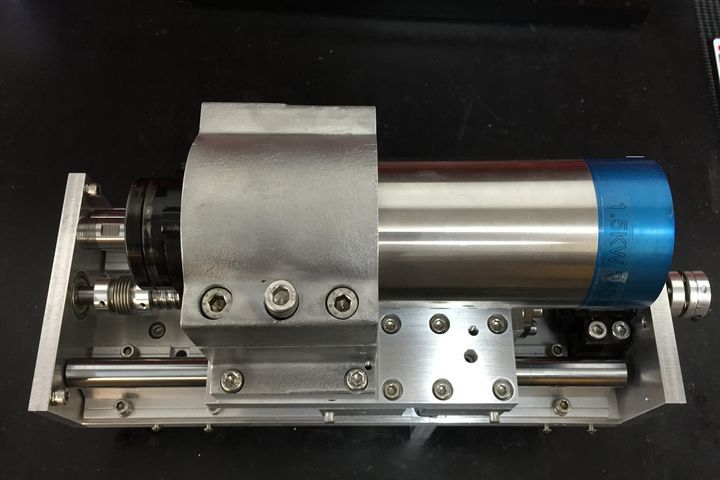

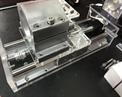

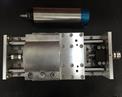

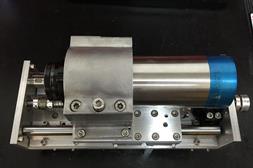

NEW Z-AXIS for CNC Router

For some time I have not been completely happy with the Z-Axis on my Home Built CNC Router, it was not quite as rigid as I would have liked and there were some other things about it that I thought could be improved on. This video shows the process of making a new improved Z-Axis. As the video shows I used my existing router to CNC all the non-purchased components. I started by making a prototype out of Clear Acrylic (Plexiglas). This allowed me to easily see and fix any errors in my design along with visualising the functionality before I committed the design to aluminium. I used the CAD/CAM software “Vectric - Aspire” that I use this for all my other projects. The first Z-Axis like the whole original CNC-Router was machined almost completely without any CNC. This time I was able to do the design in CAD and CNC machine almost all the parts. The end result was exactly what I anticipated with greater accuracy and fitting together perfectly. Just a a point of interest, all the stills and video for this production were shot using my iPhone6. I must say even viewing the YouTube video via Apple TV on my 50" Plasma Display the quality is simply amazing.

This video was edited using still images and video that I took throughout the development and assembly process.

Click the image to play the YouTube Video

Click the YouTube Logo to go to my Channel

Click the image to play the YouTube Video

Click the YouTube Logo to go to my Channel

DOWNLOADS

3D CAM Simulations (.jpg) - All Machined Parts. Exported from Vectric Aspire (zip file 519KB)

Full set of still photos (.jpg) - Those used for making the video. (zip file 5.7MB)

Scalable Vector Graphics (SVG) is an XML-based vector image format for two-dimensional graphics with support for interactivity and animation. The SVG specification is an open standard developed by the World Wide Web Consortium (W3C) since 1999.

You can download a free SVG editor/viewer: "Inkscape SVG Editor" https://inkscape.org

You can download a free SVG editor/viewer: "Inkscape SVG Editor" https://inkscape.org

Please note that all the information and downloads provided on this page are intended for personal use only.

If you intend to use any of this information for commercial purposes please contact me for authority before doing so.

If you intend to use any of this information for commercial purposes please contact me for authority before doing so.

Full video parts 1-4 same as the YouTube version .mpg-4 1280x720 (zip file 156.3MB)

Collection of Images

NOTES

Please send me a message via the Contact Me page should you notice anything that is not functioning correctly or even anything as simple as a spelling mistake.

Thank you any comments would be greatly appreciated.

Thank you any comments would be greatly appreciated.

LINKS

Re-Surfacing the MDF Bed Board - The final stage in setting up the new Z-Axis. Click to See

The purpose for the lower coupler has no technical reason. When I ordered the Rail and Ball screw kit specified as 300mm, when it arrived the ball screw total length was 300mm the same as the rails where in fact for my design I needed it to be 350mm to include the machined ends. I applied a bit of lateral thinking and as my Ball Screw Nut was located at the top of the slide I was never going to use the lower 100mm of the screw. That gave me the idea of simply extending the lower machined section with a flexible coupler into the lower bearing. In fact this worked out to be an ideal design point. I changed it to the bellows style of coupler simply because I thought it look good.

It has now been a couple of weeks since this upgrade to my router and I must say with the jobs done to date I am really pleased with the improvements.

The Z-Axis depth accuracy and consistency is improved as well I no longer have any indication of chatter at all that was an occasional problem before.

I also notice that the routed edge finish has improved.

Overall a very worthwhile upgrade. I contribute most of the improvements to the more robust/rigid spindle motor mounting.

The Z-Axis depth accuracy and consistency is improved as well I no longer have any indication of chatter at all that was an occasional problem before.

I also notice that the routed edge finish has improved.

Overall a very worthwhile upgrade. I contribute most of the improvements to the more robust/rigid spindle motor mounting.